![]()

![]()

![]()

![]() Integrated CHP Modules

Integrated CHP Modules

![]() Steam Turbine Chillers

Steam Turbine Chillers

![]() Adv. Liquid Desiccants

Adv. Liquid Desiccants

![]()

![]()

![]()

Integrated CHP Systems Corp. 50 Washington RdPrinceton Junction, NJ 08550 Phone: (609) 799-2340 |

||||

|

|

Steam Turbine-Driven Chillers:

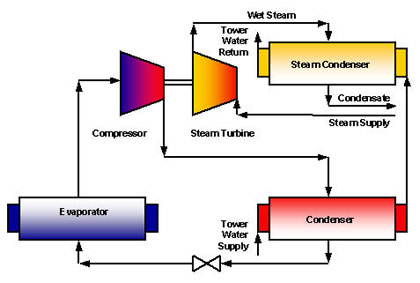

Steam turbine chillers use medium pressure steam as a motive source. Steam turbine powered chillers offer several advantages over other steam powered (double effect) absorption chillers. Off design point efficiency is superior due to the inherent use of variable speed operation and the space required for installation is less. While it is possible to design steam powered systems for almost any requirement, water chillers are usually offered for larger capacities and exceed 1,000 TR (3,500 kW) to over 8000 TR (28,000 kW). Steam sources in the range 100 to 200 psig (7 to 14 barg) are most commonly used. How They Work The principle of operation is that steam is fed to a steam turbine, which turns a compressor. The compressor provides the motive force for a traditional refrigerant vapor compression cycle where useful cooling is generated in the evaporator. Heat is rejected in the refrigerant condenser to cooling water. The same cooling water is then also passed to the steam condenser to absorb the heat required to condense the steam exiting the turbine. The condensed steam is returned to the steam generating source.

|

||||

home | services | products | market research | about us | contact us |